Location: Buffalo, New York, United States I Email: commercialengineer@davinciandtesla.com I Call us: +1 (716) 472-2893 I WhatsApp: +1 (716) 472-2893

PLANTS

DaVinci and Tesla was founded with a profound commitment to superior quality mining products, resource optimization, cost reduction, and the most respect for the dedicated labor undertaken by women and men in the mining industry.

Plants

Welcome to the world of plant solutions, where our mission is to assist you in building a new plant from the ground up or upgrading your existing facility. We offer comprehensive support from initial planning to final implementation, guided by highly skilled engineers with extensive expertise in the field. Experience the pinnacle of innovation, quality, and excellence with Davinci and Tesla.

VHC hydraulic cone crushers feature a unique design with an eccentric bushing and reinforced main shaft, enhancing crushing efficiency and durability. They offer automatic discharge during overloads and easier maintenance compared to traditional Spring Cone Crushers. Additionally, high manganese steel components extend their lifespan by 35%-82%.

The ball grinder grinds ores and materials to achieve desired granularity, widely used in metallurgy, mining, building materials, and chemicals. It consists of feeding, charging, main bearing, barrel transmission, discharging parts, and a main motor. The grinder operates through centrifugal force, friction, and gravity, crushing and grinding materials within the barrel. Optional features include air clutch, various bearing types, and magnetic lining plates, enhancing efficiency and reducing energy consumption.

The VHG series single-cylinder hydraulic cone crushers are ideal for medium and large sand and mineral processing enterprises, used for crushing class 2, 3, or 4 minerals, rocks, and bedrock. They feature high capacity, low cost, easy operation, minimal maintenance, and high efficiency. Materials are crushed in a chamber and discharged through a hopper, with an optimized design ensuring good product shape, lower production costs, and simple maintenance through hydraulic pressure adjustments. Different chamber shapes and strokes allow for versatile applications and efficient operations.

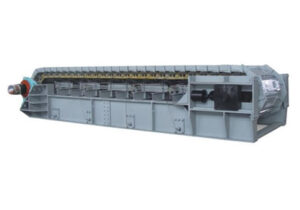

The heavy-duty apron feeder, used in mining, metallurgy, building materials, and coal industries, transports large materials over short distances, often to primary crushing equipment. It operates effectively under harsh conditions, handling both coarse and fine materials. Designed with global improvements from major suppliers, it is durable, easy to repair, and can operate at angles up to 25°.

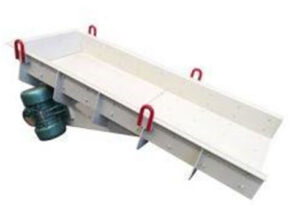

The VHG Vibrating Feeder is an inertia-driven, synchronized vibrating device widely used in mining, quarrying, coal, and food industries for continuous feeding of block and granular materials to equipment like crushers, screens, and conveyors. It can be suspended or base-mounted and features a frequency conversion motor to control feeding speed and volume.

The VHG Vibrating Feeder is an inertia-driven, synchronized vibrating device widely used in mining, quarrying, coal, and food industries for continuous feeding of block and granular materials to equipment like crushers, screens, and conveyors. It can be suspended or base-mounted and features a frequency conversion motor to control feeding speed and volume.

The VHW Series Grizzly Vibrating Feeders are designed for installation before primary jaw crushers to feed and size raw materials, made of high-strength steel to handle large rock impacts. They evenly feed the jaw crusher, remove clay and fines, and enhance primary crushing efficiency. Suitable for portable or mobile units, these feeders feature double or triple-step grizzly racks with adjustable bar spacing to increase capacity.

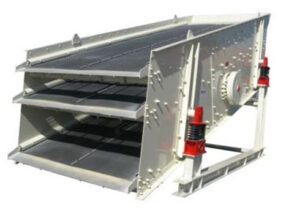

VHA inclined vibratory screens are sturdy and versatile, ideal for heavy-duty applications like coal and minerals processing. They handle both wet and dry materials, with easy installation and maintenance. Available in single, double, or triple decks, with various screen cloth options. Suitable for usual and heavy-duty operations.

VHX horizontal vibratory screens are for dehydrating, separating, and classifying materials in industries like coal and mining. They use double eccentric-shaft vibrators, require minimal maintenance with oil bath lubrication, and offer options for single or double decks and various screen cloths. The slope of the screen deck is adjustable from 0° to 5°.

DHT horizontal screens are ideal for low headroom settings like portable plants, with minimal water carryover from rinsing. Constructed with heavy-duty steel side plates for structural integrity, they handle diverse applications. Featuring three eccentric shafts and elliptical screening motion, they offer high-performance screening and precise sizing. Available in double or triple deck configurations, with options for portable or stationary setups.

Belt conveyors are commonly employed in mining, metallurgy, and coal industries for transferring loose materials or goods. They boast large capacity, simple structure, easy maintenance, and standardized components. They can operate individually or in conjunction with other conveyors, catering to diverse conveying requirements and configurations.

DOWNLOAD BROCHURE

PLANTS

We Are Your Best Choice

Your trusted broker for state-of the- art mining supplies, which in the past were exclusive to OEM and distributors.

With 35 years of combined experience, we deliver unmatched expertise and service tailored to reduce unnecessary costs in your supply chain.